In this modern world, plastic has become one of the most essential materials among us as we wake up and brush our teeth to when we go to sleep, polymers surround us in countless forms. While these materials have revolutionized our lives with their versatility, durability, and low cost, they’ve created an environmental nightmare. According to the research, more than 50 million tons of polymer waste is generated annually in India alone, with a 1.5-2% increase each year. This non-biodegradable waste can persist in the environment for thousands of years, contaminating water bodies, harming wildlife, and contributing to various health issues.

Think about your own daily plastic consumption such as water bottles, food packaging, shopping bags, and electronic casings. Most of these items are used briefly but remain in our environment for centuries. Traditional recycling methods often prove expensive and inefficient, handling only a fraction of the waste produced. The vast majority ends up in landfills, oceans, or is burned, releasing toxic chemicals into the atmosphere.

The researchers note that polymer waste is particularly problematic in developing countries like India, where rapid urbanization and growing populations have led to increased waste generation without adequate disposal infrastructure. This has created urgent environmental challenges that require innovative solutions beyond conventional recycling approaches.

The research team from Bengaluru, India saw an opportunity where others saw trash, by repurposing waste polymers into building materials. They aimed to address two critical challenges simultaneously: reducing environmental pollution and creating affordable construction materials. This approach is particularly significant in developing countries like India, where access to traditional building materials remains limited for economically disadvantaged populations1.

The researchers focused specifically on creating bricks using polypropylene (PP) fibers derived from waste polymers. Polypropylene is commonly found in products like carpets, ropes, buckets, and food containers, items that are frequently discarded after use. Rather than allowing these materials to accumulate in landfills, the team transformed them into valuable construction components.

These polymer-infused bricks aren’t just environmentally friendly alternatives to traditional bricks; they offer several potential advantages. The polymer content makes them more water-resistant, potentially lighter, and helps reduce the overall carbon footprint of construction. Imagine building a house where the walls themselves represent thousands of recycled plastic containers in construction that actively removes waste from the environment rather than generating it.

The composition of these innovative bricks includes a careful mixture of cement, fly ash, manufactured sand (M sand), and polypropylene fibers from waste polymers. Each component serves a specific purpose in the final product. Cement acts as the primary binding agent, providing structural integrity. Fly ash, a byproduct of coal combustion, helps improve workability and reduces the amount of cement needed, making the bricks more environmentally friendly. M sand, an alternative to natural river sand, provides the necessary bulk and strength, while the polypropylene fibers enhance tensile strength and reduce cracking.

Creating these bricks involves a systematic process of mixing these ingredients in precise proportions, moulding them into brick shapes, and then allowing them to cure. The curing process, where the bricks gradually harden and gain strength over time, is critical to their performance. This is why “age” emerged as one of the most important variables in predicting compressive strength in the research findings.

What makes this approach particularly valuable is that it transforms problematic waste into useful building materials. The polymer content in these bricks doesn’t degrade in the same harmful way it would in nature, instead, it becomes permanently encapsulated within the structure, effectively removing it from the waste stream.

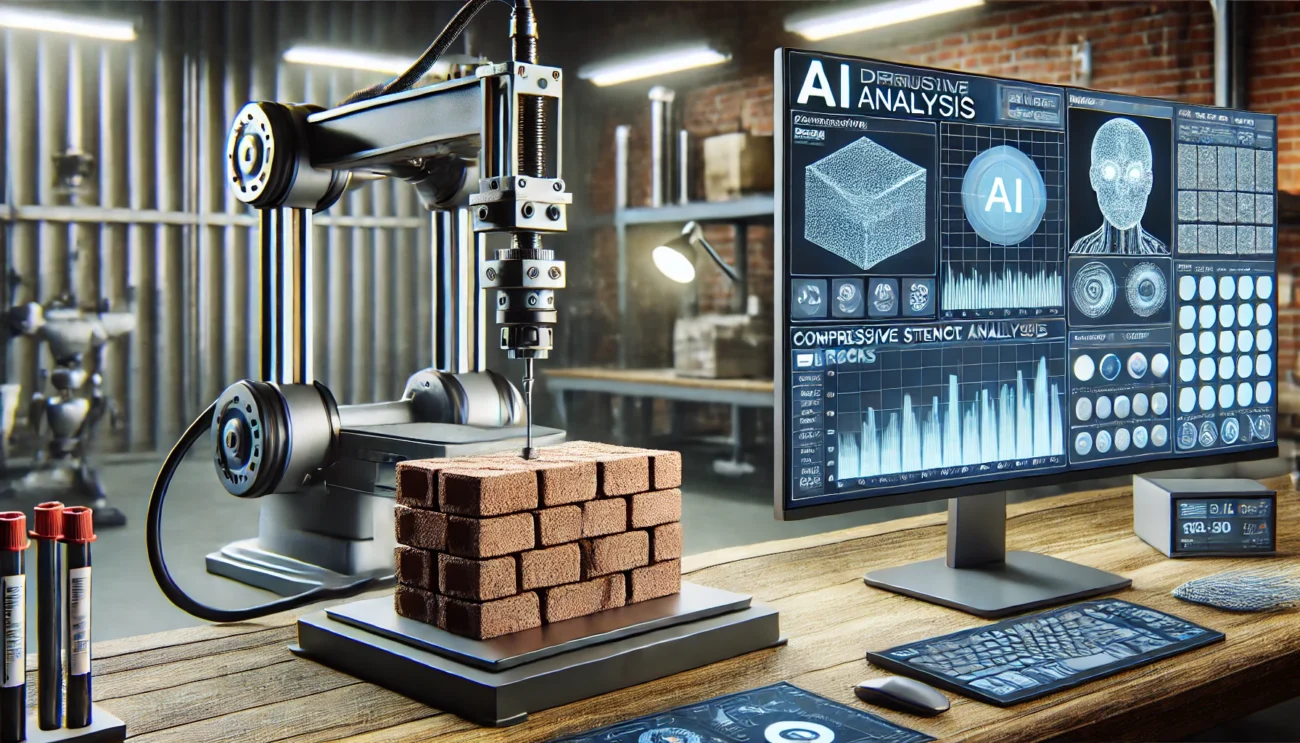

Further, the study utilizes advanced machine learning techniques to predict and optimize the compressive strength of polymer-infused bricks. Traditional material development typically relies on extensive trial-and-error testing, consuming significant time and resources. The researchers instead employed artificial neural networks (ANN), support vector machines (SVM), Random Forest (RF), and AdaBoost algorithms to create predictive models.

These machine learning approaches allowed the team to understand how different variables – cement content, fly ash proportion, M sand amount, polypropylene waste percentage, and age influence the compressive strength of the bricks. By analyzing these relationships, they could predict strength outcomes without performing physical tests for every possible combination of materials.

The researchers found that among the various models tested, Artificial Neural Networks (ANN) and Random Forest (RF) demonstrated superior accuracy. The ANN model, in particular, achieved remarkable precision with R² values of 0.99674 during training and 0.99576 in testing, along with very low error rates (RMSE values of 0.0151 and 0.01915 for training and testing, respectively). These technical metrics essentially confirm that the model’s predictions aligned almost perfectly with actual experimental results.

A common criticism of machine learning in scientific applications is that many models function as “black boxes” as they provide predictions without explaining how those predictions were derived. This lack of interpretability can be problematic in engineering applications where understanding the underlying mechanisms is crucial for safety and reliability.

The research team addressed this challenge by employing SHAP (SHapley Additive exPlanations), an innovative approach that makes machine learning models more transparent and explainable. SHAP analysis helps identify which input variables have the greatest influence on the predicted outcomes and how they interact.

Through SHAP analysis, the researchers discovered that age and fly ash content were the most important variables in predicting compressive strength. This finding makes intuitive sense that the curing time (age) directly affects how strong concrete-based materials become, while fly ash content significantly influences the chemical reactions that occur during curing.

This level of interpretability transforms machine learning from a mysterious prediction tool into a valuable scientific instrument that can enhance our understanding of material properties. Engineers can use these insights to make informed decisions about material composition based on specific strength requirements.

Polymer-infused bricks have practical applications beyond laboratories, offering real-world benefits, especially in densely populated countries like India facing housing shortages. These bricks provide an affordable, sustainable building solution for low-cost housing where traditional materials are expensive or scarce. For example, rural communities with inadequate housing and plastic waste issues can produce polymer-infused bricks locally, aiding environmental cleanup and offering affordable materials for homes and community structures. Their lightweight design reduces transportation costs and simplifies construction in remote areas.

Additionally, these bricks can be used for non-structural elements like partition walls, taking advantage of their water resistance and thermal insulation. Although the compressive strength of polymer bottles isn’t as high as concrete blocks, they are sufficient for applications like partition walls and roof slabs, and they serve as effective insulators due to their thermal resistance. Environmentally, each brick incorporates waste, potentially removing hundreds of kilograms of plastic from the environment when constructing a typical house. As this construction method scales up, the positive impact could significantly multiply.

The Broader Implications for Sustainable Construction reveal a promising intersection of waste management, material science, and artificial intelligence. The transformation of waste into resources helps in boosting the circular economy by cycling materials rather than following a linear production-waste path. The researcher’s machine learning methodology has applications beyond polymer-infused bricks to other sustainable building materials. Moreover, emphasizing interpretability through SHAP analysis tackles the critical barrier of transparency and explainability in AI adoption in engineering.

In conclusion, the research on polymer-infused bricks represents a fascinating convergence of environmental science, material engineering, and artificial intelligence. By repurposing waste polymers into valuable construction materials and using machine learning to optimize their properties, the researchers have demonstrated a pathway toward more sustainable building practices.

As we face growing challenges from both waste management and housing needs, especially in developing regions, such innovative approaches offer hope for solutions that address multiple problems simultaneously. The most remarkable aspect of this research isn’t just the creation of bricks from waste materials – it’s the demonstration that cutting-edge computational methods can accelerate the development of sustainable technologies.

Reference

Chandra, S.S., Kumar, R., Arjunasamy, A. et al. Predicting the compressive strength of polymer-infused bricks: A machine learning approach with SHAP interpretability. Sci Rep 15, 8090 (2025). https://doi.org/10.1038/s41598-025-89606-9

Kundan, Y. et al. Transforming waste into innovation: a review of plastic bricks as sustainable construction materials. Abstract Discover Civil Engineering 1(1), https://doi.org/10.1007/s44290-024-00040-8

Chao, Z. et al. Permeability and porosity of light-weight concrete with plastic waste aggregate: Experimental study and machine learning modelling. Constr. Build. Mater. 411(October 2023), 134465. https://doi.org/10.1016/j.conbuildmat.2023.134465

Arjomandi, A. et al. The effect of sulfuric acid attack on mechanical properties of steel fiber-reinforced concrete containing waste nylon aggregates: Experiments and RSM-based optimization. J. Build. Eng. 64(November 2022), 105500. https://doi.org/10.1016/j.jobe.2022.105500

akharian, P., Rezazadeh Eidgahee, D., Akbari, M., Jahangir, H. & Ali Taeb, A. Compressive strength prediction of hollow concrete masonry blocks using artificial intelligence algorithms. Structures 47, 1790–1802. https://doi.org/10.1016/j.istruc.2022.12.007