Imagine driving through a tunnel that was built over half a century ago. The concrete walls surrounding you are silently bearing the weight of earth and water, while also withstanding years of vibration from thousands of vehicles passing through daily. These aging structures require regular inspection and maintenance to ensure they don’t fail catastrophically. Until recently, this critical task fell solely to human inspectors working in difficult, sometimes dangerous conditions.

Today, an exciting technological revolution is changing how we keep our tunnels safe: robotic inspection systems. The ROBO-SPECT project, funded by the European Commission under the 7th Framework Programme, represents a significant leap forward in this field. This autonomous robotic system is designed to make tunnel inspections faster, more reliable, and less disruptive to traffic flow – all while improving the safety of both inspectors and the general public.

The global tunnel network is expanding rapidly as urban centers grow and transportation demands increase. In Europe alone, the operational length of transportation tunnels had grown to approximately 15,000 kilometers by 2002, and this number has only increased since then. Many of these tunnels were constructed over 50 years ago and have already exceeded their intended design service life. This aging infrastructure presents a significant maintenance challenge for civil engineers and transportation authorities worldwide.

Tunnels deteriorate over time due to various factors including natural aging, changes in load requirements, and environmental impacts. The structural performance degrades gradually, which necessitates regular inspection, assessment, and maintenance to ensure safety and serviceability. The traditional approach to tunnel inspection involves sending human inspectors into these confined, often unpleasant environments. These inspectors must contend with dust, humidity, poor lighting, and sometimes toxic substances while trying to identify structural issues that might compromise safety.

Manual inspection is not only uncomfortable and potentially hazardous for the inspectors but also inefficient. The process is time-consuming, requires traffic disruption, and relies heavily on the expertise and attention to detail of individual inspectors. Human factors such as fatigue and subjective judgment can lead to inconsistent inspection quality. Moreover, the increasing length and number of tunnels globally means that the demand for qualified inspectors often exceeds supply, creating a bottleneck in the maintenance process.

To appreciate the complexity of tunnel inspection, it’s helpful to understand the common defects that develop in tunnel linings. Most tunnels use reinforced concrete for their linings, sometimes covered with ceramic tiles or metal panels. While some structural problems remain hidden from view, there are several visible defects that signal potential issues.

Cracks are perhaps the most common and visible sign of structural stress. These linear fractures appear when tensile forces exceed the concrete’s strength capacity. While some cracking is normal in concrete structures, the pattern, width, and progression of cracks can indicate serious structural issues. For instance, a crack that continues to widen over time might signal ongoing settlement or pressure problems that could eventually lead to failure if not addressed.

Spalling is another common defect, characterized by the detachment of concrete chunks from the surface, leaving roughly circular or oval depressions. This often occurs due to water infiltration, freeze-thaw cycles, or corrosion of the reinforcing steel. In severe cases, spalling can expose the reinforcement bars, accelerating corrosion and weakening the structure further. A tunnel in Boston’s Big Dig project famously experienced a catastrophic ceiling panel collapse in 2006 due to anchor failure, demonstrating how seemingly minor defects can have devastating consequences.

Another defect is the efflorescence, which is a whitish deposit that forms on concrete surfaces, indicating water migration through the concrete. While not structurally threatening on its own, it signals water infiltration issues that could lead to more serious problems like reinforcement corrosion or concrete degradation. The presence of efflorescence in a tunnel might indicate problems with waterproofing or drainage systems that need addressing before more serious structural damage occurs1.

Assessing tunnel defects without causing additional damage requires specialized non-destructive evaluation (NDE) methods such as Ground-Penetrating Radar (GPR), Ultrasonic Testing (UT), Impact-Echo (IE) Testing, Infrared Thermography (IRT), Acoustic Emission (AE) Monitoring, Laser Scanning (LiDAR), Fiber Optic Sensors (FOS), Magnetic Flux Leakage (MFL), Visual Inspection (With AI and Drones). These techniques allow engineers to examine the structure’s condition without compromising its integrity. The ROBO-SPECT system incorporates several of these methods to provide comprehensive inspection data.

Visual inspection forms the foundation of most assessment protocols. Even with advanced technology, the trained human eye (or camera) remains essential for identifying surface defects like cracks, spalling, or efflorescence. However, visual methods alone cannot determine the depth of cracks or detect internal voids and delamination.

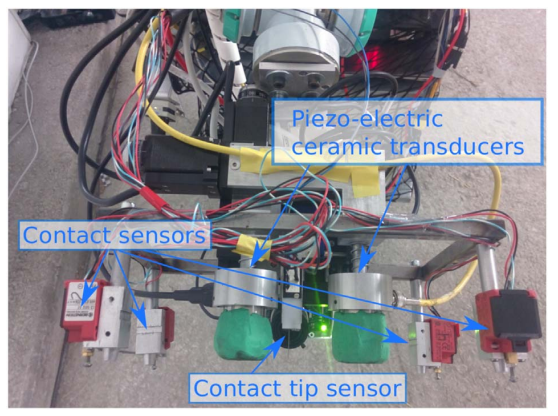

Ultrasonic methods have proven particularly valuable for concrete inspection. These techniques use high-frequency sound waves to penetrate the material and reflect off internal discontinuities. By measuring how these waves travel through concrete, inspectors can determine crack depth, detect voids, and assess material quality. The ROBO-SPECT system incorporates an ultrasonic sensor specifically designed to measure the width and depth of detected cracks, providing crucial information about their severity.

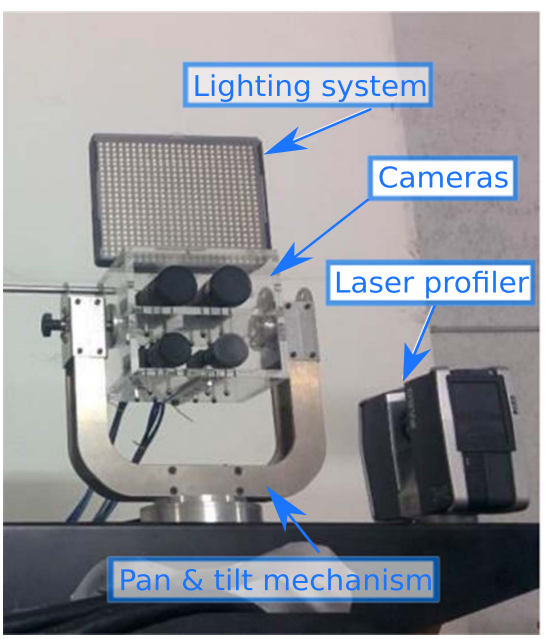

For tunnel deformation analysis, the system employs a 3D laser profiler. This technology creates detailed scans of the tunnel’s shape, allowing engineers to detect subtle changes in geometry that might indicate structural stress or ground movement. By comparing scans taken over time, engineers can identify progressive deformation before it becomes critical.

The ROBO-SPECT project represents a revolutionary approach to tunnel inspection that addresses the limitations of manual methods. Its core objective is to provide automated, faster, and more reliable tunnel inspection and assessment that minimizes traffic disruption while maximizing inspection quality.

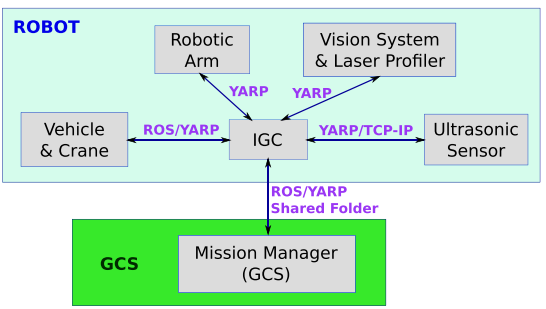

The system consists of three integrated components that work together to deliver comprehensive inspection capabilities. The first component is the robotic system itself, which performs the actual inspection inside the tunnel. The second is the Ground Control Station (GCS), which serves as the central unit for mission planning and monitoring. The third component is the Control Room (CR), equipped with computers running the Structural Assessment Tool that analyzes inspection data to generate detailed reports on tunnel conditions.

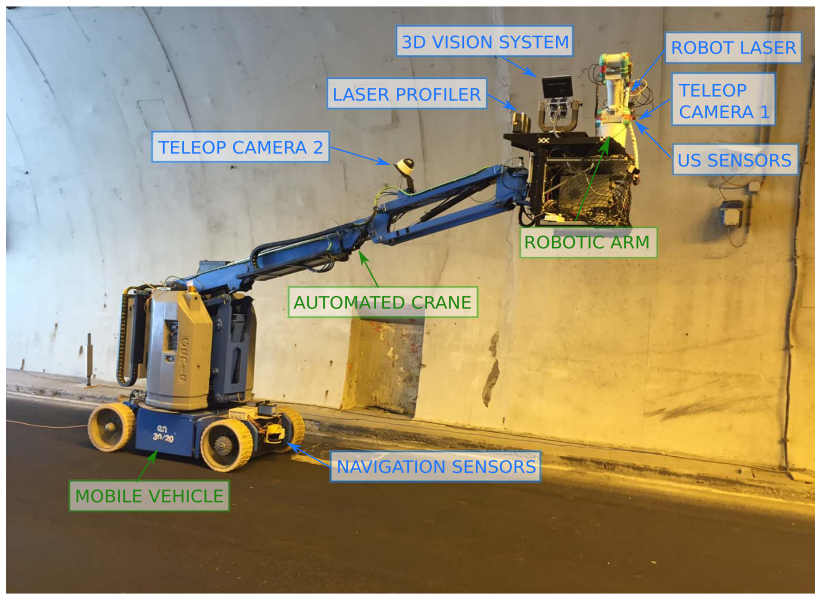

The mobile robot platform represents the heart of the ROBO-SPECT system. Based on a modified Genie Z30/20N industrial platform, this vehicle can navigate autonomously through tunnels while maintaining a constant distance from the tunnel lining. Using front and back SICK S3000 range laser navigation sensors, the robot can avoid collisions as it moves through the tunnel. To maintain precise positioning, the system employs Simultaneous Localization and Mapping (SLAM) technology with reflective beacons placed every 15 meters along the tunnel. These beacons are detected by a NAV200 navigation sensor, allowing the robot to update its position and build a 2D map of the tunnel section as it progresses.

Perhaps the most visually impressive component is the automated crane that extends from the mobile platform. This crane has been specially modified with angular and linear encoders at the joints to provide precise control over position and orientation. Special absorbers minimize vibrations, ensuring stable operation. The crane can reach heights of up to 10 meters, making it suitable for inspecting most roadway tunnels. At the tip of the crane sits a platform carrying the inspection equipment, including a robotic arm, cameras, and the 3D laser profiler.

The robotic arm itself is a marvel of precision engineering. ROBO-SPECT uses a Mitsubishi PA-10, a 7 Degree of Freedom (DoF) industrial manipulator. While only 6 DoF are needed for full position and orientation control, the extra degree provides redundancy that enhances obstacle avoidance capabilities. This arm places the ultrasonic sensor directly on cracks detected in the tunnel lining, allowing for precise measurement of crack width and depth. The effective workspace of the robot extends approximately one meter from the base of the arm to the end-effector, providing sufficient reach for detailed inspection tasks.

The traditional tunnel inspection process typically requires extensive tunnel closures, disrupting traffic and commerce. With ROBO-SPECT, only a single lane closure is necessary, minimizing disruption while still allowing for comprehensive inspection. This represents a significant advantage for busy tunnels where closures have substantial economic impacts.

The inspection process begins with mission planning at the Ground Control Station. Engineers define the section of tunnel to be inspected and establish parameters for the inspection process. Once deployed, the mobile robot navigates to the starting position and begins the systematic inspection procedure.

As the robot moves through the tunnel, its computer vision system continuously scans the tunnel lining for visible defects. Using advanced image processing algorithms, the system can detect cracks, spalling, and other surface anomalies. When a defect is identified, the system marks its location and classifies the type of defect. For cracks that require further assessment, the robot positions the crane to bring the robotic arm within range of the defect.

The precision of the robotic arm enables exact placement of the ultrasonic sensor against the crack surface. This contact measurement provides detailed information about crack width and depth that would be difficult or impossible to obtain through visual inspection alone. Meanwhile, the 3D laser profiler captures geometric data about the tunnel, allowing for detection of deformation or displacement in the tunnel structure.

All this data is transmitted to the Control Room, where the Structural Assessment Tool analyzes the findings. By integrating information about defect type, severity, and location with structural models of the tunnel, the system can assess the overall condition of the tunnel and identify areas requiring maintenance or repair. This comprehensive approach provides engineers with unprecedented insight into tunnel conditions.

The ROBO-SPECT system has been tested in Europe, including Switzerland’s VSH infrastructure, London Underground, and Egnatia Motorway tunnels. This diversity helped validate its performance under various conditions. Benefits include enhanced inspection quality and increased workplace safety by minimizing human presence in hazardous areas. The robotic inspection’s speed and efficiency lower costs and reduce service disruptions. Most importantly, its consistency ensures critical defects are detected, preventing potential failures. Future applications for ROBO-SPECT technologies include inspecting bridges, dams, and other infrastructure. As sensors and AI improve, these systems will become better at detecting structural issues.

In conclusion, the ROBO-SPECT project advances infrastructure maintenance by integrating robotics, computer vision, ultrasonic sensing, and structural analysis. It overcomes traditional inspection limitations, enhancing safety and efficiency. As our infrastructure ages, innovative solutions like ROBO-SPECT are essential for safety and functionality. Today’s autonomous robotic inspectors lead a new era of infrastructure management, ensuring bridges, tunnels, and buildings are safe for future generations.

This technology complements human expertise, allowing engineers to focus on analysis and critical decision-making instead of hazardous inspection tasks. The blend of human judgment and robotic precision enhances safety, reduces costs, and minimizes disruptions, benefiting both transportation authorities and the public.

Reference

Menendez, E., Victores, J. G., Montero, R., Martínez, S., & Balaguer, C. (2018). Tunnel structural inspection and assessment using an autonomous robotic system. Automation in Construction, 87, 117-126.https://doi.org/10.1016/j.autcon.2017.12.001

Bergeson, S. Ernst, Tunnel Operations, Maintenance, Inspection and Evaluation (TOMIE) Manual, Transportation Research Board of the National Academies, 2015, http://dx.doi.org/10.3141/2592-18

Gucunski, et al., Nondestructive testing to identify concrete bridge deck deterioration, Transportation Research Board, 2013.http://dx.doi.org/10.17226/22771

Suda, A. Tabata, J. Kawakami, T. Suzuki, Development of an impact sound diagnosis system for tunnel concrete lining, Tunneling and Underground Space Technology. Underground Space for Sustainable Urban Development. Proceedings of the 30th ITA-AITES World Tunnel Congress Singapore,22-27 May 2004, vol. 19, 2004, pp. 328–329.http://dx.doi.org/10.1016/j.tust.2004.01.026

Gucunski, S.-H. Kee, H. La, B. Basily, A. Maher, Delamination and concrete quality assessment of concrete bridge decks using a fully autonomous RABIT platform, Int. J. Struct. Monit. Maint. 2 (1) (2015) 19–34, http://dx.doi.org/10.12989/ smm.2015.2.1.019

Quigley, K. Conley, B. Gerkey, J. Faust, T. Foote, J. Leibs, R. Wheeler, A.Y. Ng, ROS: an open-source Robot Operating System, ICRA workshop on open source software, vol. 3, Kobe, Japan, 2009, p. 5. Available at https://www.willowgarage. com/sites/default/files/icraoss09-ROS.pdf