Civil engineering structures face ongoing wear and tear from environmental influences, ageing, excessive loads, and insufficient maintenance. Timely detection of damages is vital to avoid severe failures and to prolong the lifespan of structures. While conventional non-destructive testing methods like ultrasonic and X-ray inspections are useful, they tend to be both time-intensive and expensive, particularly for larger constructions.

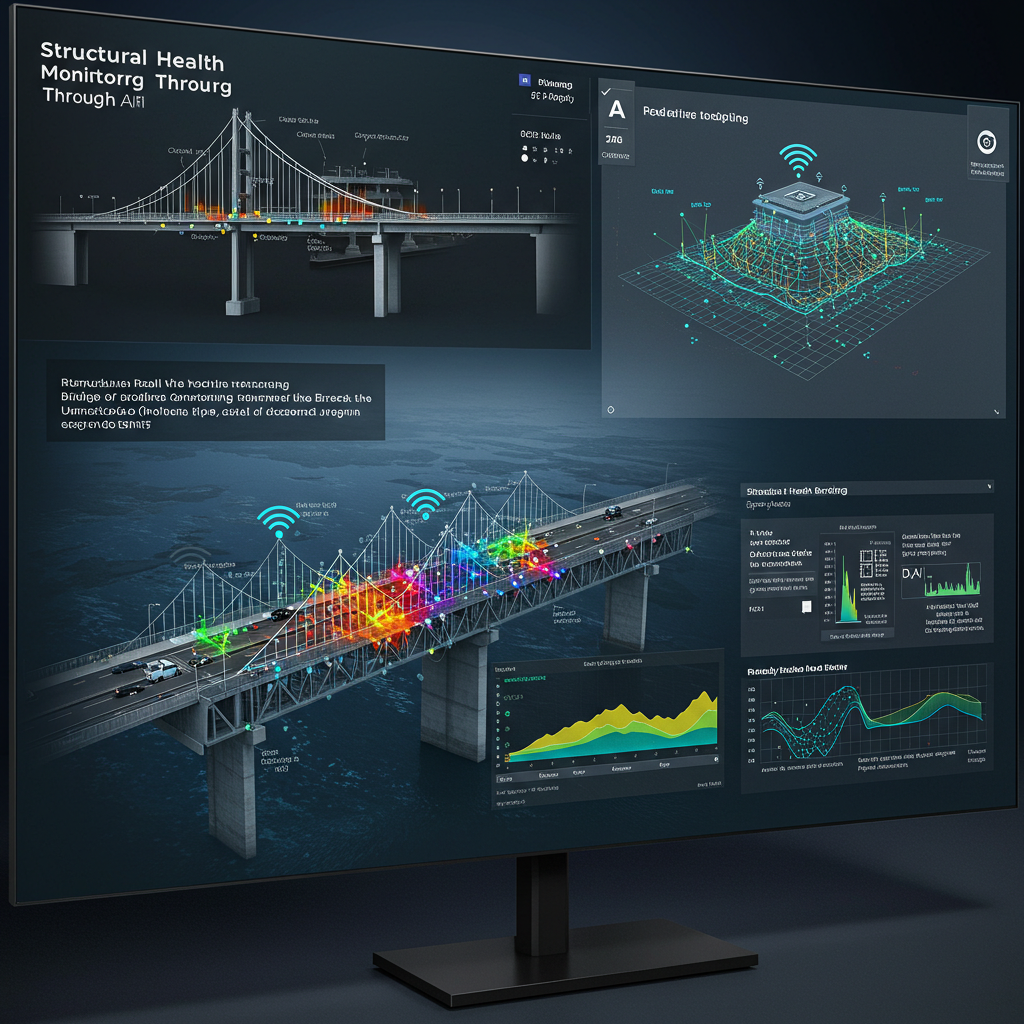

This article discusses a novel technique proposed by a team of researchers from Sydney and Hong Kong for identifying damage incorporates vibration-based monitoring, artificial neural networks (ANNs), and principal component analysis (PCA). This approach allows for efficient, dependable, and cost-effective monitoring of structural health by examining alterations in frequency response functions (FRFs).

Vibration-based techniques play a crucial role in assessing structural health by evaluating variations in mass, stiffness, and damping characteristics. When structural damage occurs, these fundamental properties are altered, resulting in changes to the dynamic response of the structure. To accurately assess this response, several key measurable dynamic quantities are taken into account.

Vibration-based damage detection methodologies identify structural damage through the analysis of changes in both physical and dynamic properties, focusing on three primary dynamic quantities: time histories, frequency response functions (FRFs), and modal parameters. Traditionally, natural frequencies and mode shapes have been the most commonly utilized features in this context. However, resonant frequencies can sometimes be insensitive to lower levels of damage and may be influenced by environmental factors. Conversely, mode shapes provide a more effective means for estimating damage location and severity; however, they necessitate extensive sensor data and are sensitive to measurement incompleteness.

On the other hand, FRF data is generally more accessible to obtain, requires fewer sensors, and involves less complex data processing, rendering it a highly effective option for real-time damage detection.

Frequency response functions (FRFs) demonstrate how a structure responds across different frequencies, showcasing its dynamic properties. Modal parameters, which encompass natural frequencies, mode shapes, and damping ratios, are essential for grasping a structure’s overall integrity and performance. FRFs are advantageous as they require fewer sensors, offer real-time data, and involve minimal human oversight. Nevertheless, dealing with full-size FRF data poses challenges due to its large volume and susceptibility to noise.

Most damage identification techniques based on vibration employ pattern recognition to distinguish between signal types, such as pre-damage and post-damage. In this realm, Artificial Neural Networks (ANNs) facilitate learning and classification. The combination of FRFs with ANNs has demonstrated potential, yet the substantial size of FRF data presents hurdles. Utilizing full FRFs complicates training efficiency, while opting for only partial FRF data may lead to the omission of vital information and detection errors.

Artificial neural networks (ANNs) excel in pattern recognition and classification. They are ideal for damage identification since they can learn complex relationships between input and output data. However, using raw FRFs as input can result in excessive computational demands.

To address this, Principal Component Analysis (PCA) is employed to compress FRF data while retaining crucial information. PCA achieves this by transforming the dataset into a smaller set of uncorrelated variables called principal components (PCs). This method reduces dimensionality and filters out noise, enhancing the reliability of damage detection.

The damage identification framework utilizes a systematic approach starting with data collection, where vibration data is obtained from either numerical simulations or real-world experiments, commonly through impact hammer testing or finite element analysis (FEA). Next, a frequency response analysis is performed, transforming time history data into frequency response functions (FRFs) via the Fast Fourier Transform (FFT). To further polish the data, feature extraction is conducted using Principal Component Analysis (PCA), which streamlines the FRFs into a condensed set of principal components, effectively removing extraneous noise while maintaining essential damage indicators. The subsequent phase involves training and testing artificial neural networks (ANNs) using the PCA-reduced FRFs, facilitating the identification of patterns indicative of damage location and severity. To boost accuracy, various neural networks, each trained on distinct sensor data, are integrated into an ensemble model. This collective method combines individual predictions, thereby enhancing the overall resilience of the damage identification process.

“A numerical model of a steel beam was created using ANSYS for finite element analysis. The beam is 2400 mm long with a cross-section of 12 mm by 32 mm, supported as pin-pin, and has a modulus of elasticity of 200,000 N/mm². The model utilized SOLID45 elements, with a specific division of mesh established through sensitivity studies. Sixteen damage cases were analyzed with notches introduced at four locations and four severities (extra light, light, medium, severe). Transient analysis under an 800 N impact force was conducted, simulating real conditions with added Gaussian noise at different levels. The response data was transformed into frequency spectra using FFT, producing 144 residual FRFs to analyze damage effects.”

“To validate a damage identification method, experimental tests were conducted on four pin–pin supported steel beam specimens at the University of Technology Sydney. The beams measured 12 mm by 32 mm by 2400 mm and were inflicted with single damages of varying severities (XL, L, M, S) at specific locations (4, 5, 6, 7) using 1 mm saw cuts of heights 1, 4, 8, and 12 mm. Impulse hammer testing was utilized to gather time response data, with measurements taken by seven piezoelectric accelerometers. The signals were amplified, recorded, and analyzed using a data acquisition system, producing frequency response functions (FRFs) through transformation into the frequency domain. Residual FRFs were calculated from data obtained before and after damage, resulting in a total of 400 FRFs across different damage cases”.

The proposed approach for detecting damage in simply supported steel beams underwent comprehensive testing through numerical simulations and laboratory experiments. Different levels of damage severity and variations in location were introduced to evaluate the technique’s accuracy. Additionally, noise sensitivity tests included the application of white Gaussian noise at various levels. The study’s key findings revealed that the Artificial Neural Network (ANN) ensemble effectively identified both the location and severity of damage in the data gathered from simulations and experiments. Furthermore, Principal Component Analysis (PCA) was useful in filtering out noise, ensuring high detection accuracy even with noise levels up to 10%. The PCA-ANN framework showed enhanced efficiency by lowering computational requirements while improving prediction reliability. Importantly, the ensemble model outperformed individual neural networks, leading to more accurate damage assessments.

The application of AI-driven methodologies in structural health monitoring holds considerable promise for real-world implementations, such as bridge inspections, the assessment of high-rise buildings, and the maintenance of aging infrastructure. However, additional research is essential to refine these methods, particularly in extending output-only Frequency Response Function (FRF) analysis for larger structures where input excitation may be impractical. It is also crucial to investigate the impact of environmental factors, such as temperature and humidity, on FRF-based detection techniques. Furthermore, the applicability of this technology to more intricate structures, including multi-story buildings and field conditions, merits examination.

In summary, the integration of Principal Component Analysis (PCA), Frequency Response Functions, and AI-driven neural networks represents a significant advancement in structural health monitoring. This innovative approach enables real-time, cost-efficient, and accurate damage detection, which is vital for promoting the longevity and safety of critical infrastructure. As AI technology continues to evolve, its importance in civil engineering is anticipated to grow, fostering the development of smarter and more resilient structures worldwide.

Reference

Li, J., Dackermann, U., Xu, Y. L., & Samali, B. (2011). Damage identification in civil engineering structures utilizing PCA‐compressed residual frequency response functions and neural network ensembles. Structural Control and Health Monitoring, 18(2), 207-226.

Adams RD, Cawley P, Pye CJ, Stone BJ. A vibration technique for non-destructively assessing the integrity of structures. Journal of Mechanical Engineering Science 1978; 20:93–100.

Kim J-T, Park J-H, Lee B-J. Vibration-based damage monitoring in model plate-girder bridges under uncertain temperature conditions. Engineering Structures 2007; 29(7):1354–1365.

Chen HL, Spyrakos CC, Venkatesh G. Evaluating structural deterioration by dynamic response. Journal of Structural Engineering 1995; 121(8):1197–1204.

Fang X, Tang J. Frequency response based damage detection using principal component analysis. Proceedings of IEEE International Conference on Information Acquisition, Hong Kong and Macau, China, 2005; 407–412.