The silent crisis of aging infrastructure affects nations worldwide, with thousands of bridges, dams, and buildings deteriorating faster than we can inspect them. As structures were built decades ago, they reach the end of their designed lifespans, the race to identify potential failures before they become catastrophic has never been more urgent. Recent advancement in artificial intelligence, particularly in deep learning and computer vision, are providing engineers with powerful new tools to detect early warning signs such as concrete cracks with unprecedented accuracy and efficiency.

This technological breakthrough is transforming how we approach infrastructure maintenance and safety. A groundbreaking study by researchers Young-Jin Cha, Wooram Choi, and Oral Büyüköztürk demonstrates how convolutional neural networks (CNNs) can accurately detect concrete cracks without the limitations of traditional methods.

The infrastructure challenge confronting contemporary societies is immense and multifaceted. In the United States, a significant portion of the transportation infrastructure, particularly bridges built during the post-World War II era—specifically between the 1950s and 1960s—was designed with an anticipated lifespan of around 50 years. As a result, a large percentage of these structures have now surpassed their intended operational lifespan, raising critical concerns about their reliability and safety.

The aging process of these bridges leads to various forms of deterioration, including corrosion of materials, cracking of concrete, and weakening of support systems. These issues not only threaten the structural integrity of the bridges but also pose serious risks to public safety, as they could lead to accidents or catastrophic failures if not addressed in a timely manner.

In light of these challenges, the American Association of State Highway and Transportation Officials (AASHTO) has underscored the urgent need for the implementation of effective inspection and maintenance protocols. These protocols must be comprehensive, incorporating advanced technologies for assessing the condition of aging infrastructure, prioritizing maintenance and repair efforts, and ensuring that funding and resources are allocated efficiently. By taking proactive steps in monitoring and maintaining these critical structures, we can safeguard public safety and extend the usable life of our transportation networks.

Traditional approaches to infrastructure monitoring rely heavily on periodic on-site inspections conducted by engineers and maintenance personnel. These human-led inspections, while thorough, come with significant drawbacks. They often require closing bridges or buildings to conduct thorough examinations, creating logistical challenges and economic impacts. Furthermore, the limited availability of qualified inspectors means that many structures cannot be assessed as frequently as needed. This reality has pushed researchers to develop more efficient structural health monitoring (SHM) techniques that can complement or partially replace human inspections.

The challenges don’t end with scheduling and resource allocation. Even when inspections occur, human inspectors face physical limitations in accessing certain areas of large structures, and their assessments can be subjective. Fatigue and environmental conditions can further impact inspection quality. These limitations highlight why technological solutions that can consistently and objectively detect structural damage are increasingly valuable to the engineering community.

Early attempts to automate crack detection primarily used various image processing techniques (IPTs). These methods manipulate digital images to extract features that might indicate structural defects. Researchers have explored numerous approaches, including the fast Haar transform, fast Fourier transform, and edge detection methods like Sobel and Canny detectors. These techniques work by analyzing pixel patterns to identify abrupt changes that might represent cracks.

For example, a comparative study by Abdel-Qader in 2003 evaluated four edge detection methods and identified the fast Haar transform as particularly effective for concrete crack detection. Later studies refined these approaches with modifications to improve accuracy under different conditions. However, these traditional image processing methods face significant limitations when applied in real-world settings.

The fundamental challenge with IPTs is their susceptibility to environmental variations. Changes in lighting conditions, shadow effects, surface textures, and camera angles can dramatically affect detection accuracy. What appears as a crack under certain lighting conditions might be indistinguishable in others. Additionally, concrete surfaces often contain various patterns and discolorations that can trigger false positives in automatic detection systems. These issues made IPTs somewhat unreliable for widespread implementation in infrastructure monitoring.

Some researchers attempted to overcome these challenges by combining IPTs with denoising techniques like total variation denoising, which can enhance edge detection by reducing image noise. However, even these advanced image processing approaches struggle with the immense variability of real-world conditions. This fundamental limitation pointed toward the need for more adaptive, learning-based solutions that could handle environmental variations more effectively.

The limitations of traditional image processing techniques (IPTs) created an opening for machine learning approaches, particularly deep learning with convolutional neural networks (CNNs). When compared to traditional methods that rely on manually engineered features, CNNs can automatically learn to identify relevant patterns from training data. This capability makes them particularly well-suited for complex visual recognition tasks like crack detection.

CNNs represent a specialized type of artificial neural network inspired by the organization of the animal visual cortex. Their architecture is designed to process grid-like data, such as images, through layers of convolutional filters that can detect increasingly complex features. The fundamental advantage of CNNs over traditional image processing methods is their ability to learn what constitutes a crack rather than being explicitly programmed with crack characteristics.

The architecture of a CNN typically includes several key components. The convolutional layers apply filters to input images, detecting features like edges, textures, and more complex patterns. Pooling layers reduce the spatial dimensions of the data, making the network more computationally efficient while preserving important information. Activation functions introduce non-linearity, allowing the network to learn complex relationships. Finally, fully connected layers integrate all the learned features to make classification decisions.

What makes CNNs particularly valuable for infrastructure inspection is their adaptability to varying conditions. Once properly trained, a CNN can recognize cracks across different lighting conditions, angles, and surface textures. This robustness addresses one of the key limitations of traditional image processing techniques.

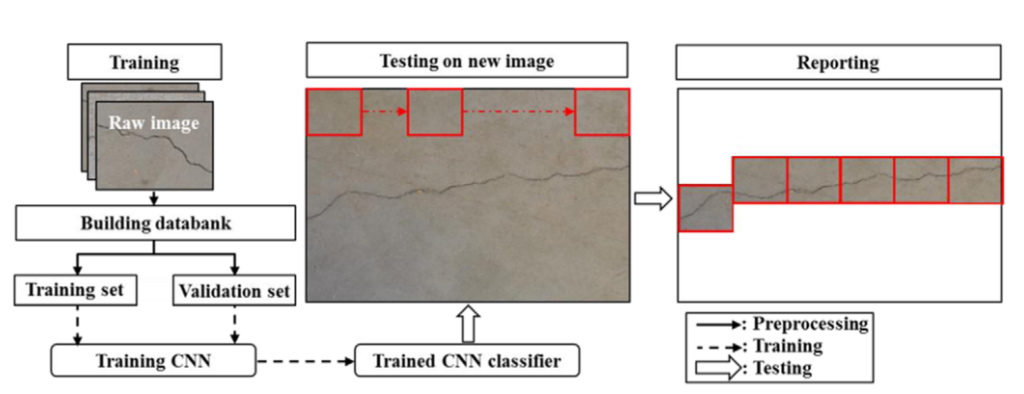

This article discusses about the research conducted by Cha, Choi, and Büyüköztürk provides a compelling demonstration of how CNNs can be applied to concrete crack detection. Their study focused on developing a robust classifier that could identify cracks despite environmental variations and noise factors that typically challenge traditional methods.

The researchers began by collecting a diverse dataset of concrete surface images. They captured 332 raw images of concrete surfaces from a complex Engineering building using a DSLR camera. These images intentionally included a wide range of variations in lighting, shadow, and other factors that might trigger false alarms in traditional detection systems. Of these images, 277 (with 4,928 × 3,264 pixel resolutions) were used for training and validation, while 55 images (with 5,888 × 3,584 pixel resolutions) were reserved for testing.

To prepare the training data, the researchers cropped the original images into smaller 256 × 256 pixel images. These cropped images were then manually annotated as either containing cracks or being intact. This process generated a comprehensive database from which training and validation sets were randomly selected.

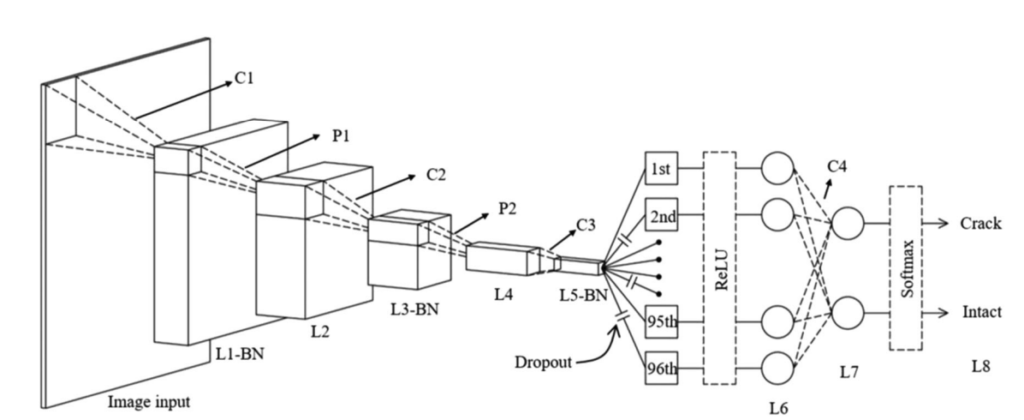

The CNN architecture developed for this study consisted of multiple layers designed to progressively extract and process image features. The network began with an input layer accepting 256 × 256 × 3 pixel images (representing height, width, and RGB channels). This was followed by several convolutional layers, pooling layers, and activation functions that gradually reduced the spatial dimensions while increasing feature depth. The final output used a softmax layer to classify each image as either cracked or intact.

The training process utilized stochastic gradient descent to optimize the network parameters. The researchers implemented additional techniques such as batch normalization and dropout to improve training stability and prevent overfitting. These methodological choices reflect the sophisticated understanding required to develop effective deep learning solutions for engineering applications.

The results were remarkable. The trained CNN achieved approximately 98% accuracy in crack detection. Even more impressively, when tested on the 55 images not used in training or validation, the network demonstrated robust performance under various challenging conditions, including strong light spots, shadows, and extremely thin cracks. This performance significantly outpaced traditional edge detection methods like Canny and Sobel, highlighting the superiority of the deep learning approach for this application.

This technology’s implications extend beyond academic research. Implementing CNN-based crack detection in infrastructure management offers practical benefits. Drones with cameras can automatically analyze images for cracks during bridge inspections, allowing inspectors to focus on flagged areas and improving efficiency. Property managers can use regular automated scanning of critical elements without disrupting operations.

It integrates into existing management systems for continuous monitoring, shifting maintenance from reactive to proactive, which can extend structure lifespans and reduce costs. It also enhances public safety by detecting cracks early, allowing maintenance teams to address potential failures and prevent costly repairs. In seismically active areas, post-earthquake assessment can be expedited with rapid automated scans for new cracks, enabling quicker decisions on occupancy and repairs.

Understanding the technical details of the CNN architecture helps appreciate the sophistication of this approach. The network described in the study consists of four convolutional layers (L1, L3, L5, and L7), two pooling layers (L2 and L4), a rectified linear unit (ReLU) layer (L6), and a softmax layer (L8).

The convolutional layers perform element-by-element multiplications between a subarray of an input array and a receptive field (also called a filter or kernel). The multiplied values are summed, and bias is added to create the output. This process effectively extracts features from the input images. The dimensions of these operations are carefully designed to progressively reduce spatial dimensions while increasing feature depth.

For example, the first convolutional operation (C1) uses 24 filters of size 20 × 20 × 3 with a stride of 2, transforming the 256 × 256 × 3 input image into a 119 × 119 × 24 feature map. The pooling layers (P1 and P2) further reduce dimensionality through downsampling, taking either the maximum or mean values from input subarrays. This reduction in spatial dimensions makes the network more computationally efficient while preserving important information.

The network also incorporates auxiliary layers such as batch normalization and dropout. Batch normalization helps stabilize and accelerate training by normalizing the inputs to each layer. Dropout randomly deactivates neurons during training to prevent overfitting, ensuring the network generalizes well to new images rather than memorizing the training data.

The CNN-based approach to crack detection has limitations, requiring substantial one-time computational resources. Performance heavily depends on quality training data, underscoring the need for diverse, well-annotated datasets. Future research should expand detection to various structural damages like delamination, voids, spalling, and corrosion. Efforts are underway to enhance CNN interpretability, helping engineers understand damage flags. Integrating with other technologies, such as vibration-based monitoring, offers a more comprehensive assessment. As deep learning advances, newer architectures like R-CNNs and YOLO (You Only Look Once) networks may enhance detection speed and accuracy, broadening their application in infrastructure maintenance.

In conclusion, deep learning, especially convolutional neural networks (CNNs), significantly enhances concrete crack detection in infrastructure maintenance. Unlike traditional image processing, this method provides reliable, efficient, and adaptable structural health monitoring tools. Research by Cha, Choi, and Büyüköztürk shows that CNNs can achieve high accuracy in challenging conditions. As infrastructure ages, effective monitoring and maintenance become increasingly critical. Deep learning enables earlier detection and tailored maintenance. While human expertise is vital in engineering, these AI tools will increasingly support decisions, ensuring safety and functionality for future generations. The journey towards fully automated infrastructure inspection is just beginning. Continued research and real-world application will drive innovation, leading to more efficient maintenance and safer, more resilient infrastructure systems globally.

Reference

Cha, Y. J., Choi, W., & Büyüköztürk, O. (2017). Deep learning‐based crack damage detection using convolutional neural networks. Computer‐Aided Civil and Infrastructure Engineering, 32(5), 361-378. https://doi.org/10.1111/mice.12263

Chang, C., Chang, C., Vavrova, M., & Mahnaz, S. (2022). Integrating Vulnerable Road User Safety Criteria into Transportation Asset Management to Prioritize Budget Allocation at the Network Level. Sustainability, 14(14), 8317.

Bengio, Y., Goodfellow, I. J. & Courville, A. (2016), Deep Learning, An MIT Press book. Online version is available at: http://www.deeplearningbook.org

Butcher, J., Day, C., Austin, J., Haycock, P., Verstraeten, D. & Schrauwen, B. (2014), Defect detection in reinforced concrete using random neural architectures, Computer-Aided Civil and Infrastructure Engineering, 29(3), 191–207.

Jahanshahi, M. R., Masri, S. F., Padgett, C. W. & Sukhatme, G. S. (2013), An innovative methodology for detection and quantification of cracks through incorporation of depth perception, Machine Vision and Applications, 24(2), 227–41.

Liu, S. W., Huang, J. H., Sung, J. C. & Lee, C. C. (2002), Detection of cracks using neural networks and computational mechanics, Computer Methods in Applied Mechanics and Engineering, 191(25–26), 2831–45.