Introduction

Imagine embarking on your daily commute, crossing a majestic bridge that arches gracefully over a river. As you drive, a sense of reassurance washes over you—you trust that the structure is sound and secure. However, just below the surface, hidden from your sight, a world of potential problems lurks. Cracks silently stretch across the concrete, while the relentless grip of corrosion begins to weaken its integrity, and sections may crumble away bit by bit.

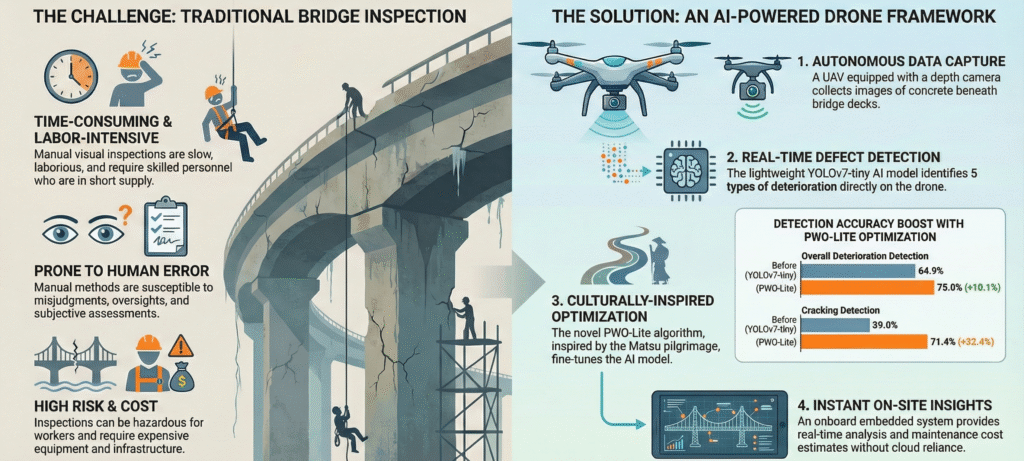

Traditionally, engineers had to rely on outdated methods to uncover these hidden issues. They would suspend themselves from ropes or erect intricate scaffolding, all for the sake of inspecting the bridge—a process that was not only slow and laborious but also riddled with risk. The efforts to identify and assess these flaws often took weeks, costing time and resources.

Now, envision a revolutionary shift in this paradigm: a drone soaring effortlessly beneath the bridge, equipped with advanced scanning technology. In just a matter of minutes, it sweeps across the surface, capturing data that reveals not only the locations of the damage but also provides immediate insights into the severity of the issues. This intelligent system can quickly estimate the costs of repairs, transforming what was once a daunting and hazardous task into a swift, efficient, and much safer operation.

This isn’t science fiction. It’s the breakthrough presented in the research by Chou and Liu, who developed an Optimized Lightweight Edge Computing Platform for UAV-Assisted Detection of Concrete Deterioration. In simple terms, they’ve created a “smart bridge doctor” that combines off-the-shelf drones with a powerful yet efficient AI system, inspired by an unexpected source: a traditional Taiwanese religious pilgrimage.

This article breaks down this fascinating research, explaining the “why,” the “how,” and the game-changing “so what” in plain language.

Why Bridge Inspection is Ripe for an Upgrade

Bridges serve as the vital arteries of our transportation infrastructure, playing a crucial role in connecting communities and facilitating the movement of goods and people. However, like any structure, they are subject to the effects of time and environmental factors. Weather conditions such as rain, snow, and extreme temperatures can weaken materials, while heavy traffic loads create stress that accelerates wear and tear. Additionally, chemical interactions, such as those caused by salt used for de-icing in winter, can lead to further deterioration of bridge components.

A seemingly minor crack in a bridge’s structure, if not addressed promptly and adequately, has the potential to evolve into a significant structural risk, jeopardizing both safety and operational integrity. For many decades, the predominant approach to assessing the condition of bridges has been through manual visual inspections.

During these inspections, trained teams of inspectors physically access the bridge to thoroughly evaluate its condition. They often employ specialized equipment, such as under-bridge inspection trucks, which allow for close-up inspections without requiring workers to suspend themselves in mid-air, as well as ropes, harnesses, and lifts for areas that are difficult to reach. The inspectors meticulously observe the bridge’s surface, tapping on various components to listen for hollow sounds that indicate potential flaws. They take precise measurements of key structural elements and capture detailed photographs to document findings and monitor changes over time. This hands-on approach, while effective, is labor-intensive and can be limited by accessibility and weather conditions, underscoring the need for innovations in inspection technology and methodology.

The drawbacks are significant:

- Time-Consuming: Inspecting a single bridge can take days.

- Labor-Intensive: It requires highly trained personnel, a profession facing shortages globally.

- Subjective: One inspector’s “minor crack” might be another’s “potential concern.”

- Dangerous: Working at heights or near traffic poses risks.

- Data Lag: Insights aren’t available until long after the inspection, delaying critical decisions.

The New Opportunity: Drones & AI

Introducing the drone, also known as an Unmanned Aerial Vehicle (UAV). Drones can effortlessly reach difficult locations, capturing hundreds of high-resolution images quickly and safely. The challenge now shifts from gathering data to understanding it. Manually analyzing thousands of drone images is impractical. This is where Artificial Intelligence (AI), particularly through computer vision, plays a crucial role.

A Three-Part AI System on a Lightweight Platform

The core of this research is a clever integration of three technologies into a system compact and efficient enough to fly on a drone.

1. The AI’s Eyes: YOLOv7-tiny & DeepSORT

The researchers needed an AI model that could identify different types of damage in real-time from a video stream. They chose YOLOv7-tiny.

What is YOLO? YOLO (You Only Look Once) is a famous family of AI models for object detection. It’s incredibly fast because it looks at an entire image once and predicts what objects are present and where they are in a single step. The “v7-tiny” version is a lightweight, streamlined variant designed for devices with limited power, like the computer on a drone.

What does it detect? The team trained YOLOv7-tiny to recognize five key types of concrete deterioration:

- Cracking (linear fractures)

- Efflorescence (white salt deposits)

- Honeycomb (rough, porous concrete surface)

- Exposed Bars (reinforcing steel becoming visible)

- Spalling (flaking or peeling of the concrete surface)

Adding Tracking with DeepSORT

A drone video is a series of images (frames). If the AI detects a crack in one frame, is it the same crack in the next frame, or a new one? DeepSORT is an algorithm that solves this. It tracks each detected flaw across frames, assigning it a unique ID. This prevents double-counting and allows the system to follow a flaw’s size and position as the drone moves.

“Think of a teacher taking attendance at a busy school gate. YOLO is their ability to quickly spot faces in the crowd (“There’s a student!”). DeepSORT is their memory that connects the face they saw at 8:05 AM to the same student walking into the hallway at 8:07, ensuring they’re only marked present once.

2. The Pilgrimage Walk Optimization (PWO-Lite) Algorithm

Here’s where it gets culturally fascinating. AI models don’t come out of the box perfectly tuned. They have dozens of dials called hyperparameters, settings that control how the model learns (e.g., learning speed, how much to adjust after an error). Setting these wrong can lead to poor accuracy.

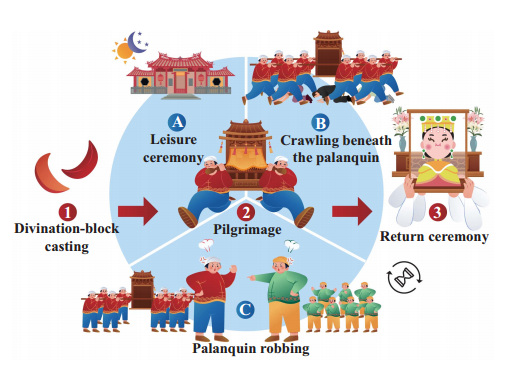

Tuning these manually is a black art. The researchers’ key innovation was to automate this using a metaheuristic optimization algorithm inspired by the Matsu Pilgrimage, a massive Taiwanese folk religious event where devotees follow a goddess’s palanquin in a dynamic procession.

How does a pilgrimage inspire an algorithm?

The original PWO algorithm mimics the crowd’s behavior:

- Exploration (Pilgrimage Phase): Devotees spread out, exploring different paths to follow the palanquin, akin to an algorithm searching a broad problem space.

- Exploitation (Bobee/Blessing Phase): When the palanquin pauses, devotees gather closely for rituals like crawling beneath it, representing the algorithm intensifying its search around a promising solution.

For this drone project, the researchers created PWO-Lite, a faster, leaner version of this algorithm. They set it a simple goal: Find the combination of 30 hyperparameters for YOLOv7-tiny that results in the most accurate damage detection.

The Result? PWO-Lite found a superior setup. When tested, the optimized model (PWO-Lite-YOLOv7-tiny) showed a 10.1% increase in overall accuracy (mAP50) compared to the default model. Most dramatically, its accuracy for detecting cracks jumped by 32.4%. The culturally-inspired algorithm literally gave the AI system a pair of better glasses.

3. Edge Computing on NVIDIA Jetson Nano

Placing a powerful desktop computer onto a drone is impractical due to concerns surrounding weight, energy consumption, and bulkiness. Instead, the key to overcoming these challenges lies in edge computing, a method that involves processing data directly at the point of collection—essentially, at the edge of the network, where the drone operates.

To harness this technology, the team ingeniously integrated their optimized AI model onto an NVIDIA Jetson Nano, a compact yet remarkably capable computer that fits comfortably in the palm of your hand. This credit-card-sized device strikes an excellent balance, offering sufficient processing power for AI applications while remaining efficient enough to operate seamlessly onboard a drone. To enhance the model’s performance further, they utilized TensorRT, an advanced NVIDIA tool designed to optimize and accelerate AI models, allowing for even more effective processing.

Featuring this diminutive onboard computer, the system is capable of processing images at an impressive rate of 10 frames per second (FPS)—a crucial capability that facilitates real-time analysis as the drone navigates through the air. Additionally, it incorporates a depth camera, specifically the Intel RealSense, which provides essential measurements of the 3D volume of any damage, such as spalling. This information is vital for accurately assessing the materials needed for repairs, enabling quick and informed decision-making during assessments.

The System in Practice

So, what does this look like for a bridge engineer?

- Flight: An engineer flies a DJI Matrice 210 drone (equipped with the Jetson Nano system) under a bridge deck. It captures live video.

- Real-Time Analysis: Onboard, the system instantly identifies and categorizes flaws, drawing colored bounding boxes around cracks, spalling, etc., on the engineer’s tablet screen.

- Tracking & Measurement: DeepSORT ensures each flaw is tracked. The system uses the bounding box dimensions and depth data to calculate: Crack length (1D), Efflorescence area (2D) and Spalling volume (3D).

- Cost Estimation: Back on the ground, the system connects to a database of local construction material and labor costs. It generates a report with a pie chart showing, for example: “Repair will require 5.2 m² of patching for honeycomb (Cost: $850) and 0.8 m³ of filling for spalling (Cost: $1,200). Total estimated cost: $4,320.“

The research validated this in lab tests, showing the system could identify about 33% of all flaw instances with a 29% error rate in measuring their size—a solid starting point for a rapid, preliminary assessment that can prioritize which bridges need closer, traditional inspection.

Why This Matters: The Bigger Picture

This work is more than a technical achievement; it’s a paradigm shift for infrastructure management.

- Safety & Prevention: Enables frequent, low-cost inspections, catching problems early before they become catastrophic.

- Efficiency: Cuts inspection time from days to hours, reduces labor needs, and minimizes traffic disruptions.

- Data-Driven Decisions: Moves maintenance from gut feeling and schedules to precise, condition-based planning. Managers can allocate limited budgets to the bridges that need it most.

- Democratization: Makes advanced inspection technology scalable and accessible, even for smaller municipalities or countries with limited engineering resources.

- Cultural Synthesis: It beautifully demonstrates how indigenous cultural practices can inspire novel solutions in modern science and technology—a true interdisciplinary breakthrough.

The Road Ahead: The researchers are upfront about next steps. Future work will involve more real-world testing under varied weather and lighting conditions, expanding the AI to detect other flaw types (like steel corrosion), and further refining measurement accuracy, possibly by integrating data from other sensors like laser scanners.

Conclusion

The research by Chou and Liu elegantly tackles a real-world problem by weaving together cutting-edge AI, clever lightweight engineering, and cultural wisdom. Their “smart bridge doctor” platform promises to make infrastructure inspection safer, faster, cheaper, and smarter.

It’s a powerful example of how technology, when thoughtfully designed and applied, doesn’t just solve technical problems—it safeguards our communities, stewards our resources, and builds a more resilient future. The next time you cross a bridge, there’s a growing chance a quiet, AI-powered drone may have already ensured your journey is a safe one.

Reference

- Chou, J. S., & Liu, C. Y. (2025). Optimized lightweight edge computing platform for uav-assisted detection of concrete deterioration beneath bridge decks. Journal of Computing in Civil Engineering, 39(1), 04024045.

- Bin Zuraimi, M. A., and F. H. K. Zaman. 2021. “Vehicle detection and tracking using YOLO and DeepSORT.” In Proc., 11th IEEE Symp. on Computer Applications and Industrial Electronics (ISCAIE), 23–29. New York: IEEE.

- Fujita, Y., K. Shimada, M. Ichihara, and Y. Hamamoto. 2017. “A method based on machine learning using hand-crafted features for crack detection from asphalt pavement surface images.” In Proc., Int. Conf. on Quality Control by Artificial Vision 2017, 103380I. Washington, DC: SPIE