Introduction

We rarely think about what happens after we flush the toilet or drain the sink. That water, now wastewater, embarks on a hidden journey through miles of pipes, ending up at a facility tasked with an almost miraculous transformation: turning sewage back into safe water. This process is critical for public health and environmental protection, yet it’s often an invisible, underappreciated engineering marvel. But what if we could make these plants not only effective but also smarter, more efficient, and predictive? Recent research from India is doing just that, using a form of artificial intelligence called a Polynomial Neural Network (PNN) to model, predict, and optimize sewage treatment.

Let’s dive into how this works and why it matters for our future.

The Problem: Why Our Sewage Plants Need a Brain Boost

First, the sobering context. In India alone, approximately 62,000 million litres of wastewater are generated daily. However, the existing Sewage Treatment Plants (STPs) can only handle about 37% of this volume. Many plants are dysfunctional, operate below capacity, or lack advanced treatment stages. The result? Only about 30% of the wastewater produced gets properly treated and recycled. The rest can pollute rivers and groundwater, leading to severe health hazards like typhoid, kidney damage, and even cancer.

Globally, the challenge is similar: treatment plants are complex, energy-intensive systems. They must handle wildly variable inflows, think of the difference between a slow Sunday and a heavy rainstorm, and remove a cocktail of pollutants including organic matter, chemicals, and solids. Traditional methods rely on fixed processes and human oversight, which can be slow to adapt to changes. This is where intelligent modeling comes in.

The Solution: Enter the Polynomial Neural Network (PNN)

So, what is this PNN, and how is it different from other AI we hear about?

Imagine you’re trying to predict the outcome of a football game. You’d consider various factors: team skill, player injuries, weather, home advantage. A simple model might add these factors up. But we know the real world isn’t simple addition; it’s about complex, non-linear interactions. The weather might affect one team’s strategy more than another’s, and an injury might be more devastating in a key position.

A Polynomial Neural Network is designed for exactly this kind of complex, multi-variable, non-linear problem. Unlike simpler linear models, a PNN can map intricate relationships between inputs (like the concentration of raw sewage) and outputs (the clean water quality). It does this by building a network of “neurons” that use polynomial equations (think advanced, multi-term math functions) to learn patterns.

Why PNN over other AI? The study compared PNN to other common models like Multi-Layer Perceptron (MLP) and found that PNN offered lower training error, faster learning, and greater interpretability for the messy, non-linear world of wastewater chemistry. It’s particularly good at handling the unpredictable swings in sewage composition.

The Experiment: From Ghaziabad’s Sewers to a Digital Model

Researchers from SRM Institute of Science and Technology and Voice of Environment chose a sewage treatment plant in Ghaziabad, India, as their testing ground. Their goal was clear: build a digital twin of the plant using a PNN to predict the quality of the treated water.

Step 1: The Data Collection

For six months, they collected water samples at three key points in the treatment journey:

- The Inlet: The raw, untreated sewage.

- Primary Sedimentation Tank (PST): After large solids have settled out.

- Final Stage Treatment (FST): The end product, ready for discharge or reuse.

They didn’t just collect a few samples; they measured ten crucial parameters:

- BOD (Biochemical Oxygen Demand): How much oxygen microbes need to break down organic waste. High BOD = very polluted water.

- COD (Chemical Oxygen Demand): The amount of oxygen required to chemically oxidize pollutants. A broader measure than BOD.

- TSS (Total Suspended Solids): The visible, solid particles floating in the water.

- pH: Acidity or alkalinity.

- OA (Oxygen Absorption): Indicates oxidizable matter.

- TS/TDS (Total Solids/Dissolved Solids): All solid material.

- Chloride, Alkalinity, Oil & Grease.

This gave them a rich, real-world dataset of how the plant performed under normal operating conditions.

Step 2: The AI Training

They fed this data into the PNN model, using 18 datasets (12 for training, 3 for validation, 3 for testing). The AI’s job was to learn the mathematical relationship between the dirty water coming in and the clean water going out.

To find the best model, they tested several advanced algorithms:

- COM (Combinatorial): Tries combinations of parameters.

- SFS (Stepwise Forward Selection): Adds the most helpful parameters one by one.

- SMS (Stepwise Mixed Selection): More flexible—can add and remove parameters to find the optimal mix.

- GNN (GMDH Neural Network): A specific type of PNN that builds layers of polynomial equations automatically.

Think of this like tuning a race car. You adjust the fuel mixture, tire pressure, and gear ratios (different algorithms and parameters) until you find the configuration that gives you the fastest, most reliable lap time (the most accurate predictions).

The Remarkable Results: An AI That Predicts Purity

The performance of the PNN model was impressive:

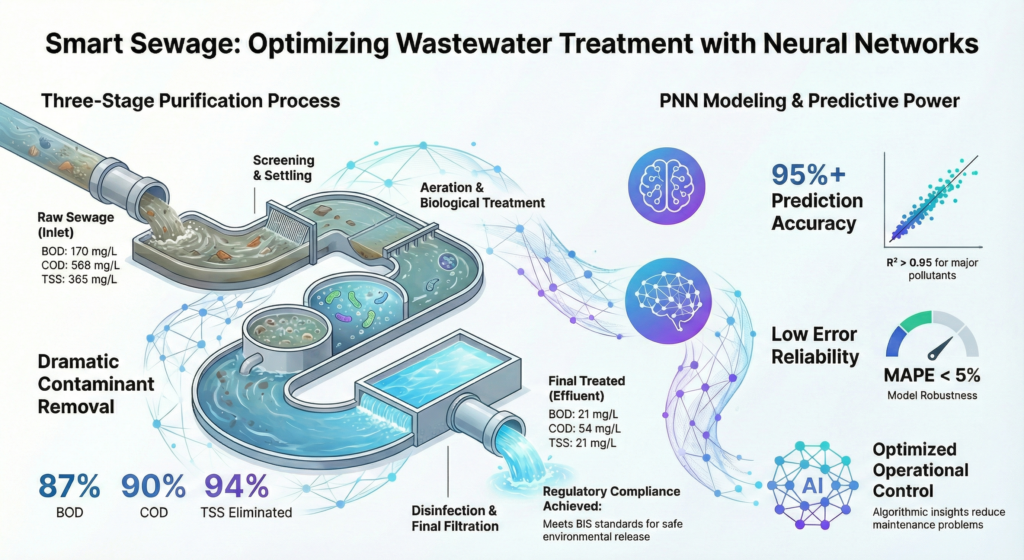

- Outstanding Prediction Accuracy: For the core pollution indicators, the model achieved a prediction accuracy (R²) of over 0.95 for BOD, COD, and TSS removal. In simpler terms, the AI could predict the treated water quality with over 95% accuracy based on the incoming sewage.

- Proven Treatment Efficiency: The plant itself was effective. It achieved massive reductions:

- BOD reduced by 87% (from ~170 mg/L to 23 mg/L).

- COD reduced by 90% (from ~568 mg/L to 53 mg/L).

- TSS reduced by 94% (from 365 mg/L to 21 mg/L).

- Model Robustness: The model’s error margin was low, with a Mean Absolute Percentage Error (MAPE) of less than 5%, confirmed by cross-validation. This means it wasn’t just memorizing data; it had genuinely learned the underlying process.

The Real-World “Aha!” Moment:

What does this mean in practice? Let’s use a real-life analogy. Imagine you’re the plant manager. A forecast predicts a massive storm tomorrow. You know stormwater will flood into the sewers, dramatically diluting the incoming sewage but also potentially overwhelming the system. With this PNN model, you could simulate this scenario in advance. You’d input the expected “weaker but voluminous” sewage profile into the digital model. It would predict that your biological treatment stage (which relies on microbes to eat waste) might struggle because the “food” (organic matter) is too diluted. The AI could then recommend an adjustment, perhaps slowing down the flow or adding a supplemental carbon source, to keep the process stable. This is predictive and proactive management, moving from reactive crisis control to intelligent optimization.

The Nuances and Limitations: Where the AI’s Crystal Ball Gets Fuzzy

The study also revealed crucial nuances, which is where true scientific insight lies.

The PNN excelled at predicting parameters with high variability and clear physical removal mechanisms, like BOD, COD, and TSS. These are mostly removed by physical settling and microbial digestion, processes the AI could easily map.

However, it struggled with parameters like pH, OA, and Alkalinity. Why?

- Low Variability: Their values didn’t change much through the plant, so the AI had less “signal” to learn from.

- Chemical & Biological Non-Linearity: These parameters are influenced by complex, often stochastic chemical reactions and biological activity. For example, pH can be affected by the breakdown of one compound that produces an acid, immediately neutralized by another reaction producing a base. This dance is harder for the model to capture perfectly.

- The “Chemical Dose” Problem: Adjusting pH often involves adding precise amounts of lime or acid. The relationship between dose and final pH is highly non-linear and depends on the exact chemical makeup of the wastewater at that second—a level of chaos that challenges even advanced models.

This teaches us a vital lesson: AI is a powerful tool, not a magic wand. It augments human expertise, handling the predictable heavy lifting (like forecasting solid removal) so that engineers can focus their attention on the more complex, nuanced chemistry.

Conclusion

The recent study conducted in Ghaziabad signifies much more than a mere academic endeavor; it serves as a compelling proof-of-concept that artificial intelligence can play a vital role as the brain behind our essential water infrastructure systems. By developing a sophisticated digital twin of a sewage treatment plant, we can transition away from traditional methods that rely heavily on guesswork and manual adjustments. Instead, we are moving toward a paradigm of precision management, predictive analytics, and proactive oversight.

When you next consider the wastewater that departs from your home, envision it flowing into a facility that is far more than just an assemblage of tanks and filtration systems. Imagine it as a dynamic, learning, and adaptive intelligent ecosystem. In this futuristic system, artificial intelligence intelligently manages intricate calculations and data analysis, accurately predicting the optimal conditions necessary for beneficial microbes to flourish and for chemical reactions to occur at their most effective levels. This not only enhances the treatment process but also guarantees that every drop of water returned to the environment meets the highest standards of cleanliness.

This innovative approach represents the next frontier in environmental stewardship, a visionary future where technology and ecological responsibility work in harmony to promote a cleaner and healthier planet. The evolution from treating sewage to ensuring safety and sustainability is becoming increasingly sophisticated, with advanced algorithms and polynomial equations driving improvements and efficiencies at every stage of the process. Through this integration of AI and water management, we are paving the way toward a more sustainable future, one intelligent calculation at a time.

Reference:

Singh, B.P., Choudhury, M., Roy, R. et al. Performance Modelling of Sewage Treatment Plant by the Application of Polynomial Neural Network. Water Air Soil Pollut 237, 512 (2026). https://doi.org/10.1007/s11270-026-09205-w