Imagine you’re a railway engineer in Japan, staring at a decades-old concrete bridge column that needs urgent strengthening. You know the trains can’t stop running, the workspace is cramped between busy tracks, and you have hundreds more columns just like this one waiting for your attention. Welcome to one of modern infrastructure’s biggest headaches.

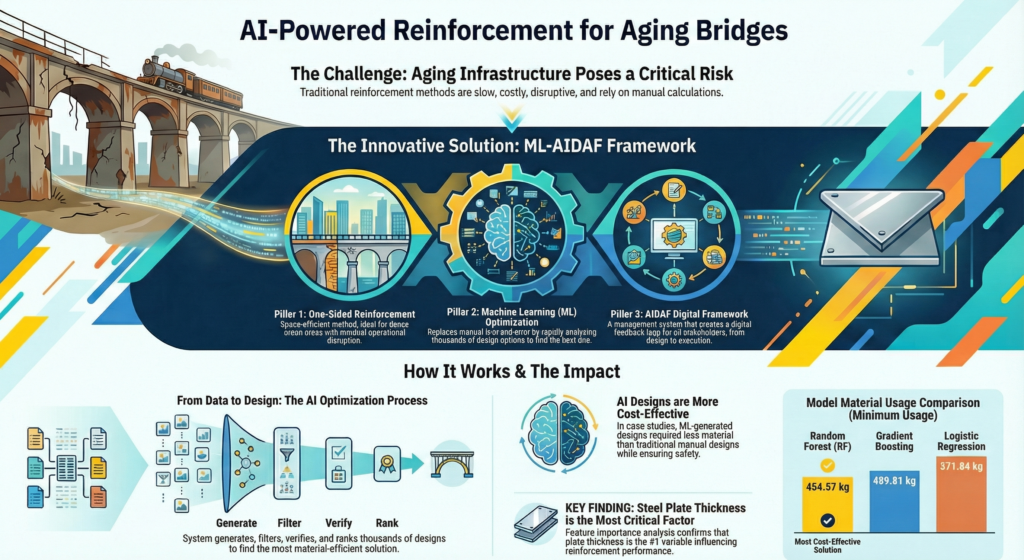

But here’s where it gets interesting: researchers have just figured out how to use artificial intelligence to solve this exact problem, cutting design time from half a day per column to mere seconds. Let me explain how they did it, and why this matters for cities around the world.

The Problem: When Infrastructure Gets Old

Japan finds itself grappling with a significant infrastructure challenge, emblematic of broader issues that many developed nations will soon encounter. During the explosive economic growth of the mid-to-late 20th century, thousands of railway viaducts crafted from reinforced concrete were erected across the country. Today, these towering structures stand at a crossroads, approaching or even surpassing their intended lifespan of 50 years.

The statistics paint a troubling picture. The Japanese Ministry of Land, Infrastructure, Transport, and Tourism has projected a dramatic increase in the percentage of bridges exceeding 50 years of age within the next decade. Compounding this issue is an aging population coupled with a dwindling pool of skilled engineers, creating a perfect storm that could lead to a severe infrastructure crisis.

The old concrete columns that support these railway systems face a myriad of threats. They are vulnerable to carbonization spurred by air pollution, corrosion of their steel reinforcements, a decline in material strength, and fatigue cracking resulting from decades of relentless vibrations caused by passing trains. Particularly alarming is the seismic safety of these aging structures in a country that frequently experiences earthquakes. Should maintenance be neglected, these critical infrastructures could experience catastrophic failures during a major seismic event, posing grave risks to public safety.

Traditional Solutions Fall Short

Conventional methods for strengthening bridge columns include wrapping them with steel plates, adding reinforced concrete layers, applying prestressed reinforcement, or using fiber-reinforced composites. While these techniques work, they come with serious drawbacks:

- Construction takes too long: Traditional methods often require extensive formwork and construction time, meaning trains must be halted or rerouted

- Space constraints: Urban railway viaducts are typically surrounded by roads, buildings, and other infrastructure, leaving little room for construction equipment

- High labor costs: Each strengthening design requires experienced engineers to manually calculate and verify safety parameters, a process that takes roughly half a working day per column

- Repetitive work: With hundreds or thousands of columns to strengthen, engineers face mind-numbing repetition of similar calculations

“Think about it: If a railway company has 500 columns needing strengthening, and each one requires 4 hours of engineering time, that’s 2,000 hours of highly skilled labor, about one person working full-time for an entire year, just on design calculations.”

Enter the One-Sided Reinforcement Method

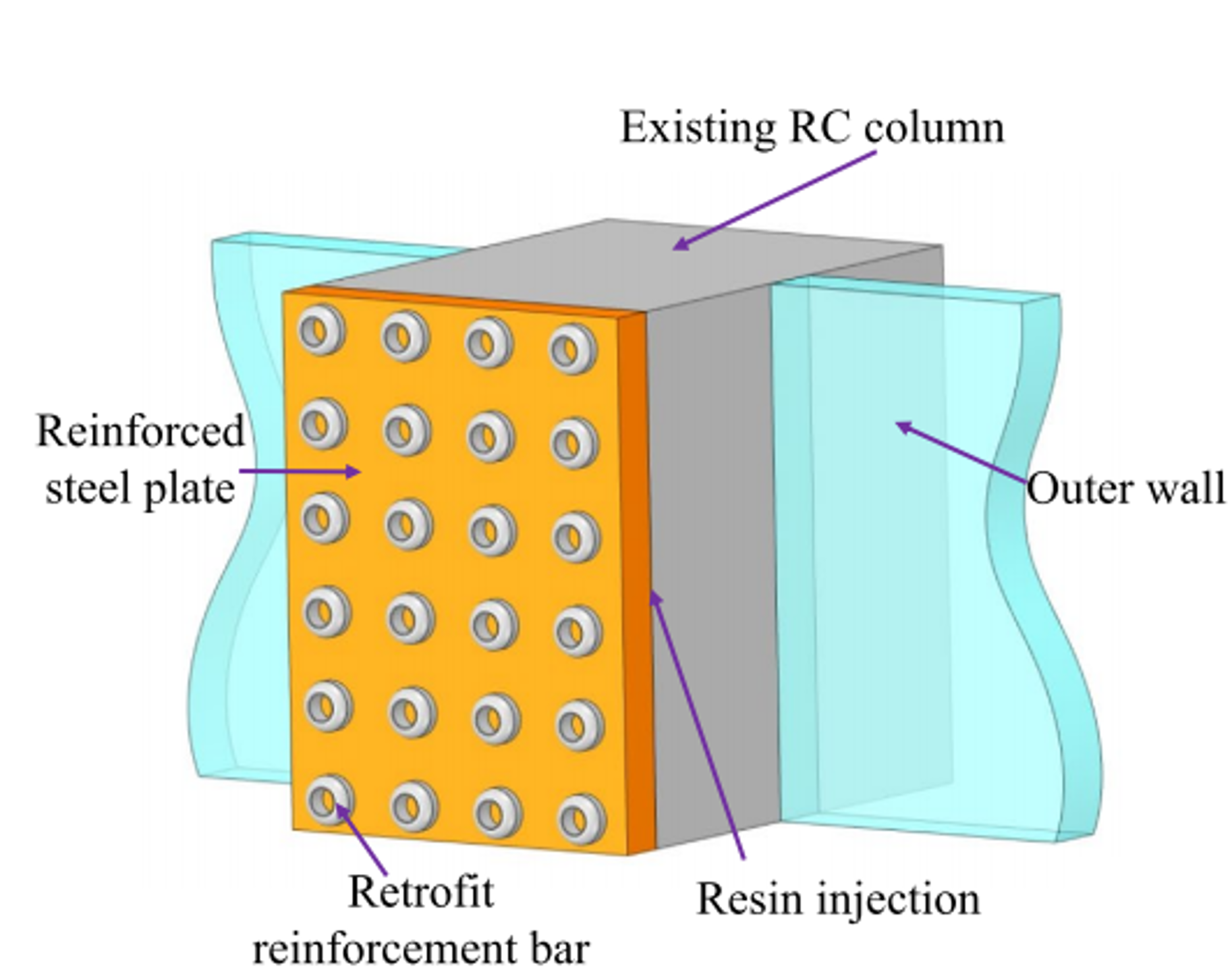

Japanese engineers developed a clever solution called the “one-sided reinforcement method.” Instead of wrapping the entire column, they install steel plates and reinforcing bars on just one side, typically the side adjacent to the maintenance walkway, where construction crews can easily access.

“Here’s how it works: Workers anchor steel reinforcing bars to the column’s surface using specialized adhesives and high-strength bolts. Then they attach external steel plates to form a composite structure that works together with the original concrete column. The key design principle is ensuring the steel plates yield (bend) before the reinforcing bars fail, maximizing the structure’s ability to absorb earthquake energy.”

This method offers several advantages:

- Minimal disruption: Since work happens on only one side, trains can continue running on the opposite tracks during construction

- Space-efficient: Perfect for cramped urban environments where full-column access is impossible

- Quick installation: Prefabricated components can be rapidly assembled on-site

- Improved performance: The method simultaneously increases shear strength, ductility, and seismic resistance.

However, the design process remains complex. Engineers must consider multiple variables such as, steel plate thickness, reinforcing bar diameter and spacing, anchor bolt positioning, and how these interact with the existing column’s geometry and material properties. Each design typically generates a report exceeding ten pages, with extensive manual calculations and iterative refinements.

The AI Revolution: From Days to Seconds

This is where the research team’s innovation becomes truly transformative. They combined three powerful elements:

- The Random Forest Algorithm

At the heart of their system is a machine learning technique called Random Forest (RF). Think of it as assembling a panel of expert consultants, where each consultant (decision tree) has learned from past successful and failed designs.

When evaluating a new column reinforcement design, each “expert” in the panel votes on whether the design is safe or unsafe. The final decision comes from tallying these votes. Because each expert learned from slightly different data and focuses on different aspects of the design, the collective judgment is more reliable than any single expert.

The researchers trained their RF model on thousands of design configurations, teaching it to recognize patterns that distinguish safe designs from unsafe ones. The model learned, for instance, that thicker steel plates generally mean safer structures, and that certain combinations of reinforcement spacing and bar diameter work better than others.

- The AIDAF Framework

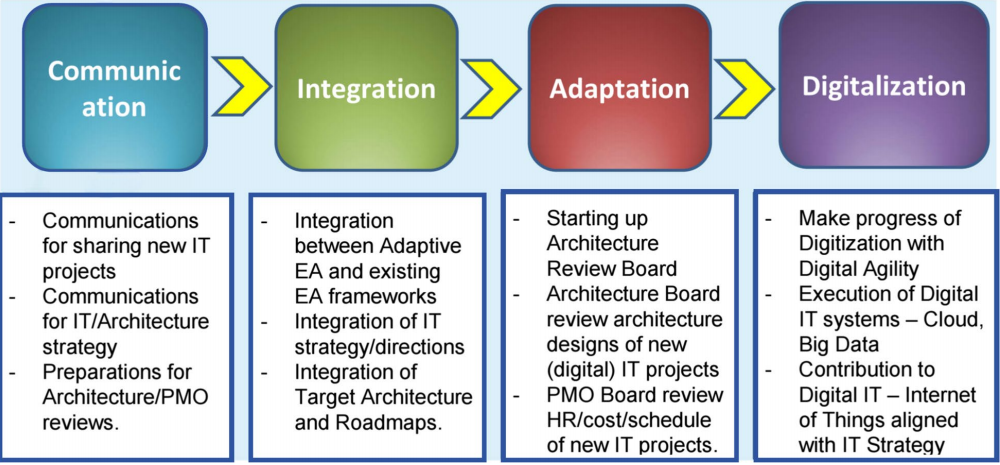

The team integrated their AI model within something called the Adaptive Integrated Digital Architecture Framework (AIDAF). This framework provides a structured approach to managing the entire lifecycle of infrastructure projects through five stages:

- Communication: Sharing information about the bridge’s condition among all stakeholders

- Integration: Combining sensor data, inspection reports, and structural models

- Adaptation: Continuously adjusting designs based on new information

- Digitalization: Creating digital twins, virtual replicas of physical bridges that can be tested and optimized

“Think of AIDAF as the operating system that allows different tools, data sources, and stakeholders to work together seamlessly. It ensures that when a bridge inspector uploads new damage photos, when an engineer proposes a strengthening design, and when a construction manager schedules work, everyone is operating from the same up-to-date information.”

- Automated Safety Verification

The researchers didn’t just let the AI make unchecked recommendations; they built in rigorous safety checks based on established engineering codes. Every design the AI suggests must pass multiple structural calculations verifying:

- Shear strength exceeds required capacity by appropriate safety margins

- Reinforcement spacing meets code requirements

- Anchorage systems can handle expected loads

- Bending strength is adequate

This hybrid approach—AI for rapid exploration of possibilities, followed by rigorous engineering verification—ensures both speed and safety.

Real-World Results: The Proof is in the Numbers

The team tested their system on actual railway viaduct columns, comparing AI-generated designs against traditional manual designs.

The results were impressive:

In one case, the AI reduced material requirements from 279.66 kg to 274.63 kg—a modest 2% savings, but across hundreds of columns, this adds up to significant cost reductions. More interestingly, in another case, the AI selected a different steel grade (SD345 instead of SD390) that engineers hadn’t considered, saving over 13 kg of material while maintaining comparable safety.

But the real victory wasn’t in material savings—it was in time. While traditional methods require experienced engineers roughly 4 hours per column for design and verification, the AI system evaluates tens of thousands of design combinations in minutes. This represents a time savings of over 99%.

Let’s put this in perspective with a real-world scenario: Imagine a railway company needs to strengthen 300 columns across their network.

Using traditional methods:

- 300 columns × 4 hours = 1,200 engineering hours

- At 8 hours per workday = 150 workdays (about 7 months of full-time work)

- Estimated cost: roughly $150,000-200,000 in engineering labor

With the AI system:

- Initial design exploration: minutes per column

- Final verification: about 30 minutes per column

- Total time: approximately 150 hours (less than 4 weeks)

- Estimated cost savings: over 80%

What Makes This Approach Smart

The researchers’ feature importance analysis revealed fascinating insights about what really matters in column strengthening:

- Steel plate thickness emerged as the most critical factor—thicker plates dramatically improve safety margins

- Reinforcing bar diameter ranked second in importance

- Spacing between reinforcement significantly affects performance

- Material grade showed surprisingly low importance, suggesting that configuration matters more than premium materials

This knowledge helps engineers focus their attention on the parameters that truly drive performance, rather than obsessing over less impactful details.

The AI model also learned some nuanced patterns that might not be obvious to human designers. For instance, it discovered that certain combinations of thin plates with closely-spaced reinforcement can achieve similar performance to thicker plates with wider spacing—but at lower material cost.

Beyond Japan: A Global Solution

While this research focused on Japanese railway bridges, the approach has worldwide relevance. The United States, for example, has over 600,000 bridges, with roughly 40% over 50 years old. Europe faces similar challenges. Even emerging economies building new infrastructure today will face these same aging issues in coming decades.

The beauty of this AI-enhanced framework is its adaptability. The same approach can be:

- Retrained for different bridge types: Highway bridges, pedestrian bridges, or building columns

- Adjusted for regional differences: Different seismic zones, climate conditions, or building codes

- Extended to other infrastructure: Tunnels, dams, or buildings facing similar aging challenges

The key is having sufficient training data—examples of past designs, their outcomes, and the engineering calculations behind them. As more infrastructure agencies digitize their records, the potential for AI-assisted design grows exponentially.

The Human Element Remains Crucial

It’s important to understand what this AI system does and doesn’t do. It doesn’t replace engineers—it amplifies their capabilities.

Human engineers still need to:

- Inspect bridges and assess damage

- Define safety requirements and design constraints

- Review and approve AI-generated designs

- Make final decisions when multiple options exist

- Handle unusual cases outside the AI’s training data

The AI serves as an intelligent assistant that rapidly explores design possibilities, flagging promising options for human review. Think of it like having a brilliant but inexperienced junior engineer who can crunch numbers incredibly fast but needs supervision from experienced professionals.

The Future of Infrastructure Management

This research points toward a future where infrastructure management becomes increasingly proactive and data-driven. Imagine:

- Real-time monitoring: Sensors on bridge columns continuously measure stress, vibration, and damage, feeding data directly into AI systems that predict maintenance needs before failures occur.

- Digital twins: Virtual replicas of entire railway networks where engineers can test strengthening strategies, simulate earthquake scenarios, and optimize maintenance schedules without disrupting actual operations.

- Automated design: AI systems that not only recommend strengthening designs but also generate construction schedules, estimate costs, and coordinate with contractors—all while ensuring trains continue running on time.

- Predictive maintenance: Machine learning models that analyze decades of bridge performance data to predict which structures need attention next year, next month, or next week.

The researchers suggest several directions for future development:

- Explainable AI: Making the AI’s decision-making process more transparent, so engineers can understand why certain designs are recommended

- Expanded training data: Including more diverse bridge types, damage patterns, and strengthening methods

- Integration with construction: Connecting design optimization directly with construction planning and cost estimation

- Lifecycle analysis: Considering not just initial strengthening costs but long-term maintenance and eventual replacement

Lessons for Infrastructure Management

This research offers several important lessons for infrastructure managers and policymakers:

- Start digitizing now: The foundation for AI-assisted design is comprehensive digital records. Infrastructure agencies should prioritize digitizing inspection reports, design documents, and maintenance histories.

- Invest in training data: The quality of AI systems depends on the quality of their training data. Systematic documentation of past projects creates invaluable datasets for future AI applications.

- Embrace hybrid approaches: The most effective solutions combine AI’s computational power with human expertise and judgment. Neither alone is sufficient.

- Think systematically: Modern infrastructure management requires integrated systems that connect inspection, design, construction, and monitoring. Piecemeal solutions won’t deliver transformative benefits.

- Plan for adaptation: Infrastructure needs evolve over time. Systems should be designed for continuous learning and improvement as new data becomes available.

Conclusion

Japan’s aging railway bridges face challenges that many countries will soon confront. The combination of AI, specifically Random Forest algorithms, with structured frameworks like AIDAF, offers a practical path forward.

By reducing design time from hours to seconds while maintaining rigorous safety standards, this approach makes it economically feasible to properly maintain and strengthen aging infrastructure. The 99% time savings translates directly to cost savings and faster project completion—critical advantages when facing thousands of structures needing attention.

More importantly, this research demonstrates that AI in civil engineering isn’t science fiction—it’s a practical tool available today. The technology works with existing design codes, leverages conventional strengthening methods, and integrates smoothly into current engineering workflows.

As our infrastructure ages and maintenance backlogs grow, innovations like this aren’t just nice to have—they’re essential. The choice isn’t between traditional methods and AI; it’s between a future where we can proactively maintain our infrastructure efficiently, or one where limited resources force us into reactive, costly emergency repairs.

Reference

- Cao, Y., Nishimura, A., Liu, Z. et al. Performance analysis and optimization of aging railway viaduct RC columns strengthened with ML-enhanced AIDAF framework. AI Civ. Eng. 4, 30 (2025). https://doi.org/10.1007/s43503-025-00079-1

- Chang, S. Y., Chen, T. W., Tran, N. C., et al. (2014). Seismic retrofitting of RC columns with RC jackets and wing walls with different structural details. Earthquake. Eng. Eng, 13, 279–292.

- Lin, M. L., Chen, P. C., Tsai, K. C., Yu, Y. J., & Liu, J. G. (2010). Seismic steel jacketing of rectangular RC bridge columns for the mitigation of lap-splice failures. Earthquake Engineering & Structural Dynamics, 39, 1687–1710.

- Sun, H., Burton, H. V., & Huang, H. (2021). Machine learning applications for building structural design and performance assessment: State-of-the-art review. Journal of Building Engineering, 33, Article 101816.